3

YEARS WARRANTY

SINCE 1932!

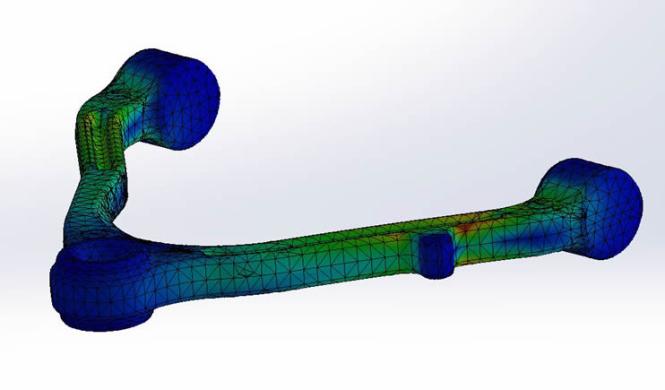

Research & Development

How to ensure consistent quality at the highest level, at all times? For FRAP the answer is development: an annual investment in technology and research of about 10% of the turnover.

Finite element analysis, three-dimensional measurements, ultrasound control of cast iron and micrographic analysis, crack detection by magnetoscope, measurement of the hardened surface layer by microdurometer, fatigue tests for silentblocs and steering rods are just some of the tools essential to maintaining quality and continuous improvement of the product.

FRAP S.p.A. - Via Volvera, 112 - 10090 - Bruino (TO) - ITALY - Tel. +39 011/9048489 - Fax +39 011/9048492 - E-mail: info@frap.it

Registered offices: Corso Galileo Ferraris, 14 - 10121 - Torino ITALY - N° RI / Cod. Fisc. / P.Iva 03738020019 - REA: 582939 - Share capital: € 1.640.000,00 fully deposited

Privacy & Cookie Policy - Cookie preferences

Registered offices: Corso Galileo Ferraris, 14 - 10121 - Torino ITALY - N° RI / Cod. Fisc. / P.Iva 03738020019 - REA: 582939 - Share capital: € 1.640.000,00 fully deposited

Privacy & Cookie Policy - Cookie preferences